Our AGILOX Corporate Blog

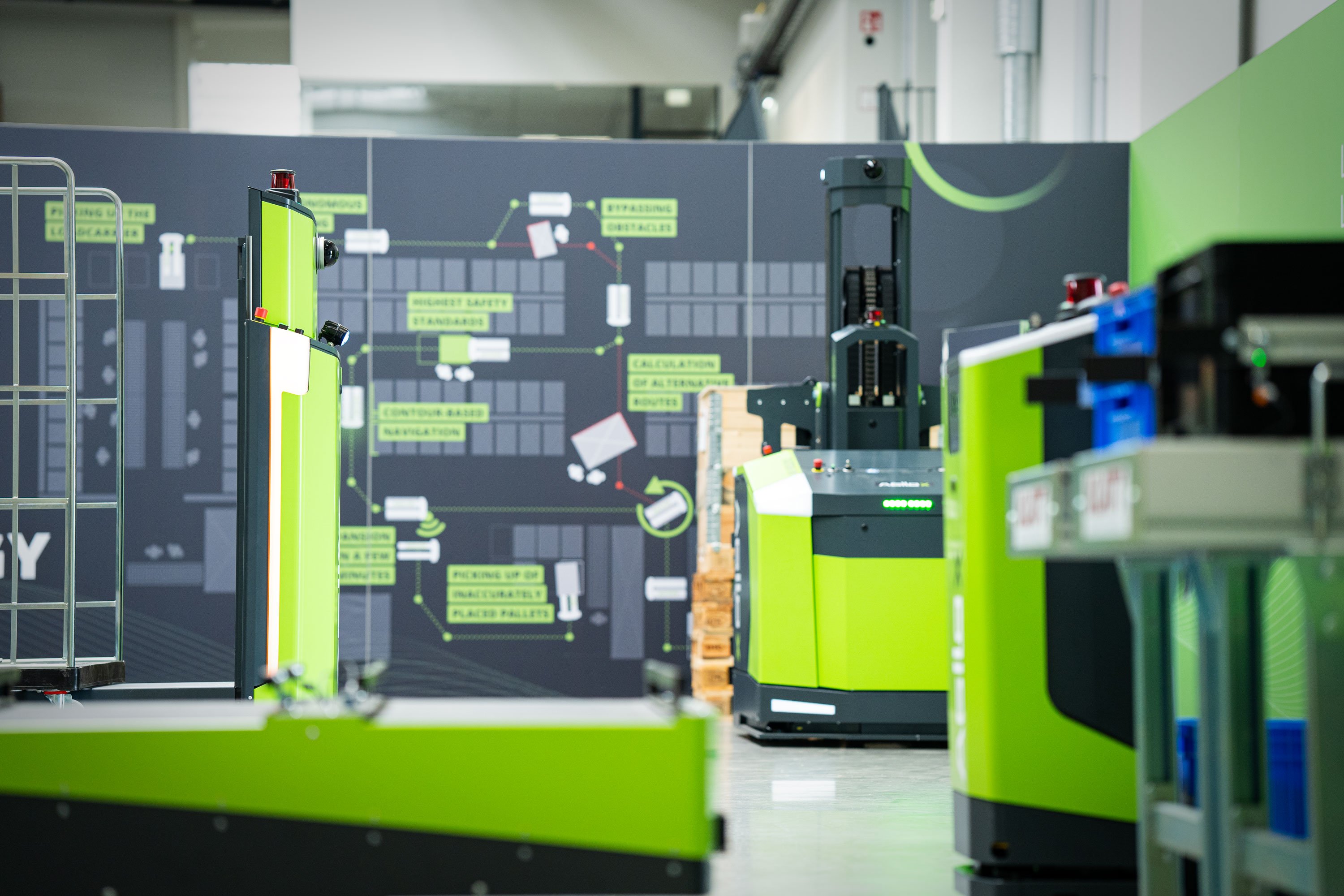

In our AGILOX Corporate Blog, we regularly report on exciting developments in the logistics industry, as well as technical facts about Autonomous Mobile Robots (AMRs). You can’t get enough of AGILOX? Neither can we! That’s why we keep you up to date with news about the company and our product portfolio. But the blog also gives our customers a chance to have their say. After all, who could tell our success story more authentically than them? Be curious!